What we do:

What our clients say:

Penn Testing has always been a great service. They are responsive, professional, and their expertise have helped Bridesburg become a leader in the Navy castings business. Our company has benefited from using their services. They are someone you can always depend on.

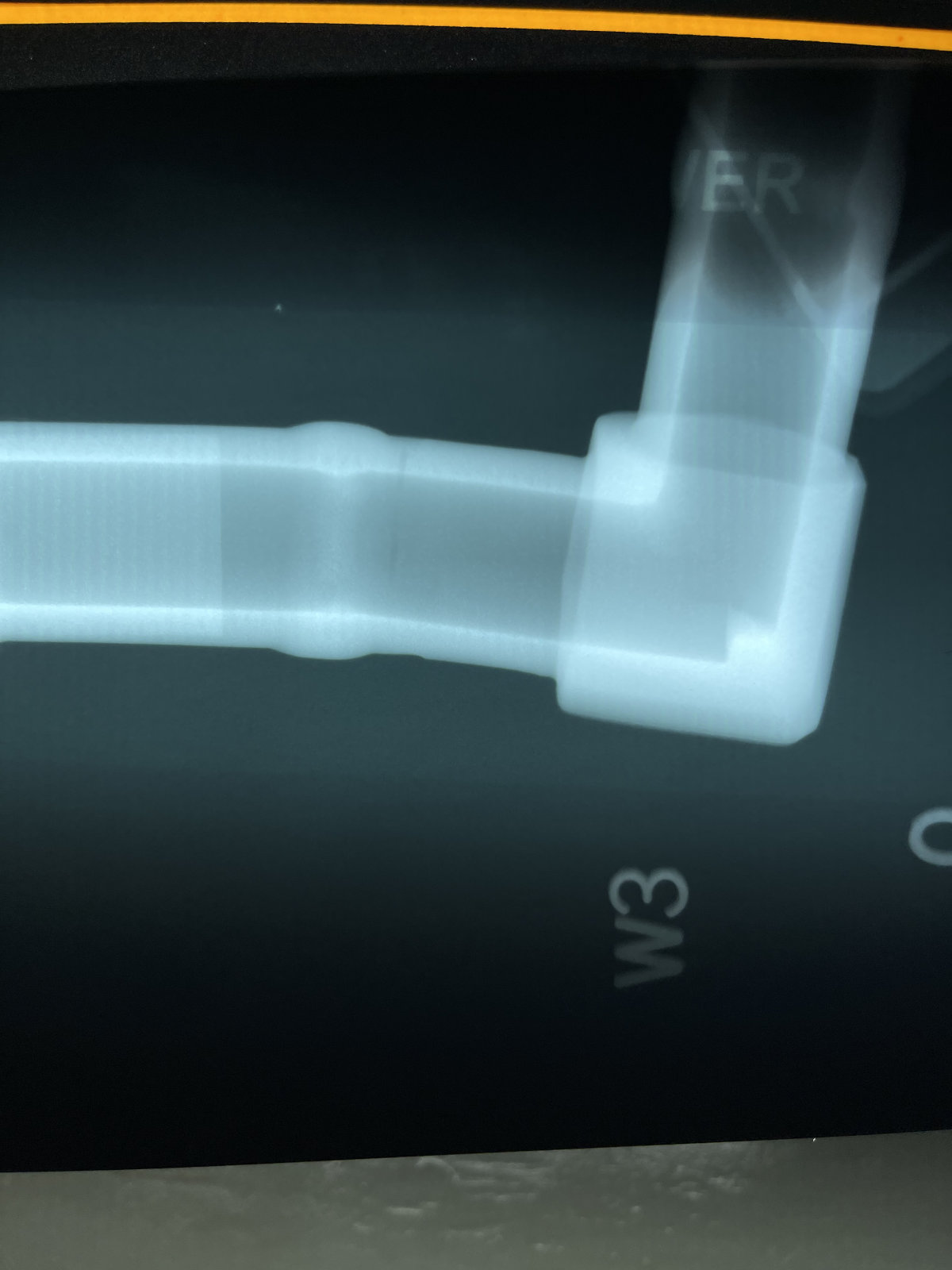

Penn Testing has been a very reliable resource for our pressure vessel x-ray and PMI needs for the past years. Their expertise, along with their quick turnaround times (sometimes while I wait at their facility) has been instrumental with keeping our projects on schedule.

Their knowledgeable staff is very helpful when providing information on x-ray results and their communication concerning project completion, issues with specimens, and overall customer service is second to none. They’ve always gone above and beyond to meet our testing and QC needs.

Your Content Goes Here